In order to achieve required leak-proof tightening of bolted flange joint assembly, appropriate bolt tightening method is used. Proper tightening of flange joint assembly creates compressive forces on gasket and pre-tensioning in bolts. As per bolt tightening methods or guidelines, cross tightening sequence is followed. Several cross tightening methods are available such as hand torque, slug/hand wrench, hydraulic torque, hydraulic tensioner etc.

Guidelines for bolt tightening:

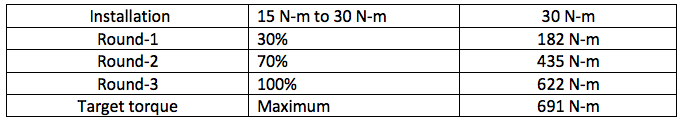

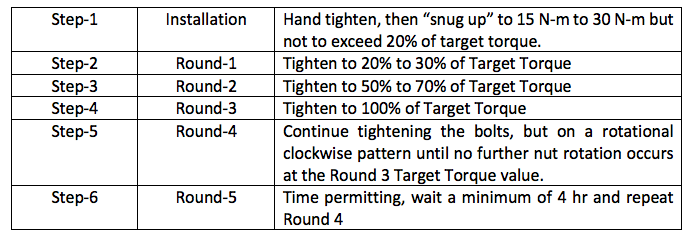

As per guidelines are given in “ASME PCC-1 Guidelines for Pressure Boundary Bolted Flange Joint Assembly”, torque increments for bolt tightening are given as follows:

Target torque for bolt tightening is calculated as per ASME PCC-1, Appendix-K as follows:

Target torque, T = K*D*F

Where,

T = Target torque, N.mm (in.lb.)

K = Nut factor

D = Nominal bolt diameter, mm (in.)

F = Target bolt load, N (lb)

Example:

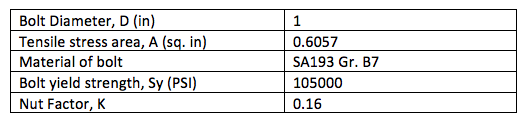

Let us consider 1’’ bolt of SA193 Gr. B7 is required for flange joint material with nut factor of 0.16. We will evaluate target bolt torque required for leak-proof tightening.

Bolt load calculation:

Maximum bolting torque is considered to develop 40% to 60% of bolt yield stress. Here we will consider bolt torque to produce 60% of bolt yield stress. Therefore,

Bolt load, F = A*Sy*0.60

= 0.6057*105000*0.6

= 38159.1 lb

Target torque calculations:

Target torque, T = K*D*F

= 0.16*(1/12)*38159.1

= 508.79 lb-ft.

Considering 10% bolt relaxation,

Suggested tightening torque, T = 0.9*508.79 = 457.9 lb-ft. (622.76 N-m)

Therefore, bolt tightening torque increments for considered bolts is as follows,