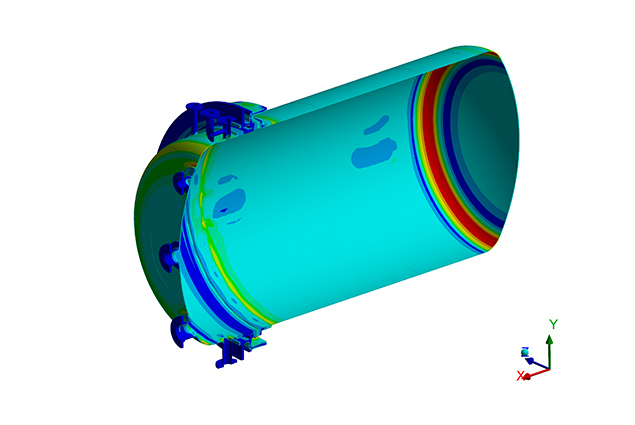

Post weld heat treatment (PWHT) is controlled process in which a material that has been welded is reheated to a temperature below its lower critical transformation temperature, and then is held at that temperature for the specified amount of time. The need of PWHT is mostly due to residual stresses and microstructural changes that occur after welding. During the welding process, a high-temperature gradient is experienced between the weld metal and parent metal. Codes like ASME specify the specific requirements for PWHT of materials. The PWHT requirements discussed in this document are in accordance with ASME Sec. VIII Div. 1.

ASME Sec. VIII Div. 1 specifies the PWHT requirements for materials used in equipment designed as per ASME. Tables UCS-56-1 through UCS-56-11 in ASME Sec. VIII Div.1 provides heating cycle data required for PWHT of materials based on P No. and Gr. No as categorized in ASME Sec. IX. Those tables are followed by notes which provide exemptions. Table UCS-56.1 gives alternative heat treatment requirements for carbon and low alloy steels. Before applying for the detailed requirements and exemptions, satisfactory weld procedure qualifications of the procedures to be used shall be performed in accordance with all the essential variables of ASME Section IX including conditions of post weld heat treatment.

PWHT requirements as per ASME Sec. VIII Div. 1

Most commonly used materials for process equipment comes under P.No.-1 & Gr.No.1,2,3,4. PWHT for carbon and low alloy steels- P. No. 1 & Gr.No.1,2,3,4 are given below

PWHT for carbon and low alloy steels- P. No. 1 & Gr.No.1,2,3,4

Postweld heat treatment is mandatory under the following conditions

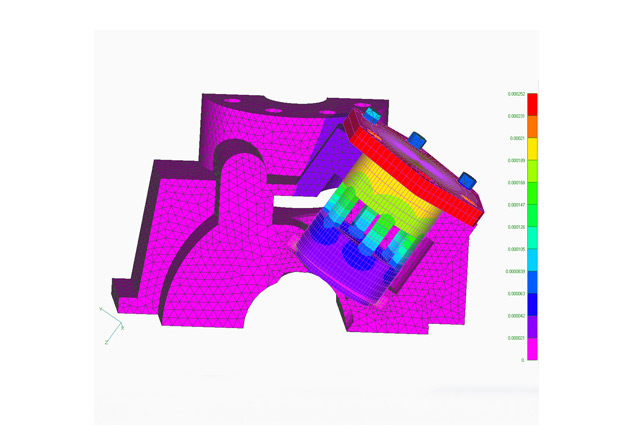

a. for groove welds not over 1/2 in. (13 mm) size and fillet welds with a throat not over 1/2 in. (13 mm) that attach nozzle connections that have a finished inside diameter not greater than 2 in. (50 mm), provided the connections do not form ligaments that require an increase in the shell or head thickness, and preheat to a minimum temperature of 200°F (95°C) is applied

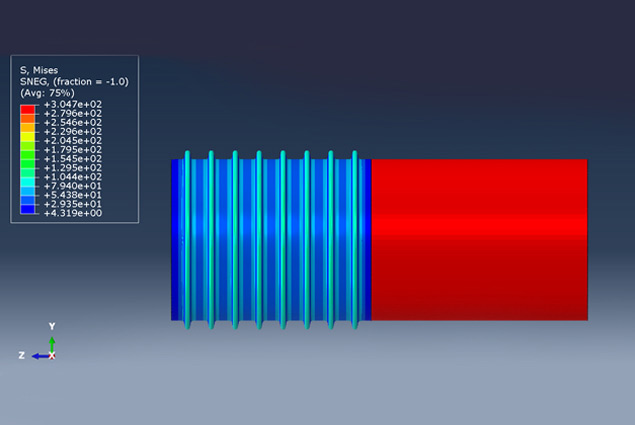

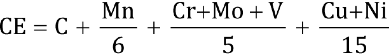

b. for groove welds not over 1/2 in. (13 mm) in size or fillet welds with a throat thickness of 1/2 in. (13 mm) or less that attach tubes to a tubesheet when the tube diameter does not exceed 2 in. (50 mm). A preheat of 200°F (95°C) minimum must be applied when the carbon content of the tubesheet exceeds 0.22%.

c. for groove welds not over 1/2 in. (13 mm) in size or fillet welds with a throat thickness of 1/2 in. (13 mm) or less used for attaching non-pressure parts to pressure parts provided preheat to a minimum temperature of 200°F (95°C) is applied when the thickness of the pressure part exceeds 11/4 in. (32 mm).

d. for studs welded to pressure parts provided preheat to a minimum temperature of 200°F (95°C) is applied when the thickness of the pressure part exceeds 11/4 in. (32 mm)

e. for corrosion resistant weld metal overlay cladding or for welds attaching corrosion resistant applied lining (see UCL 34) provided preheat to a minimum temperature of 200°F (95°C) is maintained during application of the first layer when the thickness of the pressure part exceeds 11/4 in. (32 mm)