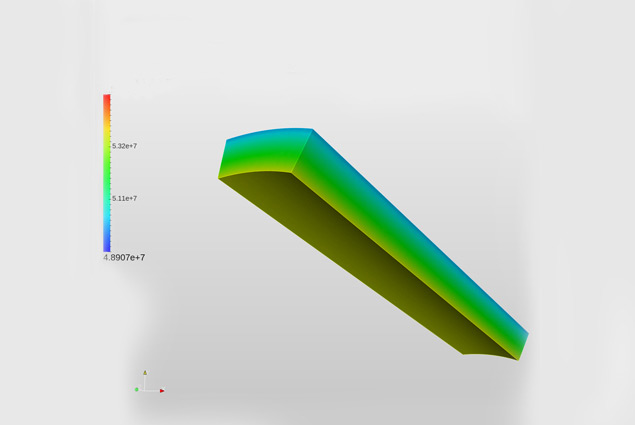

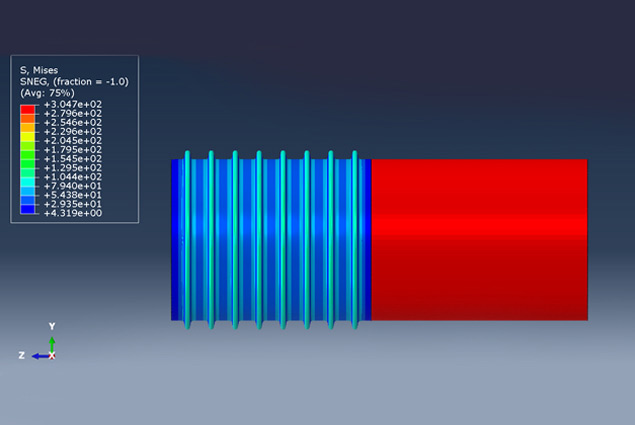

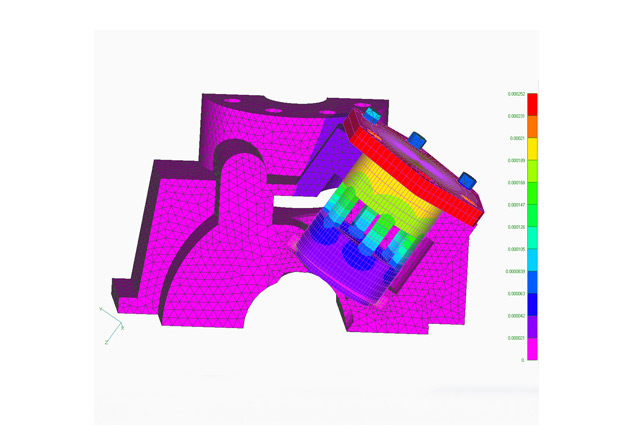

Mounded Bullet FEA Analysis

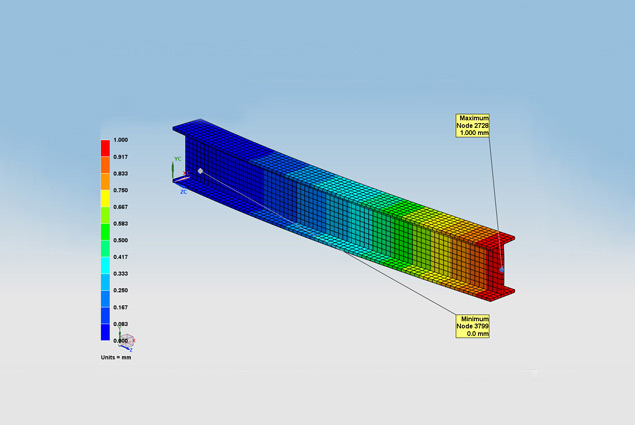

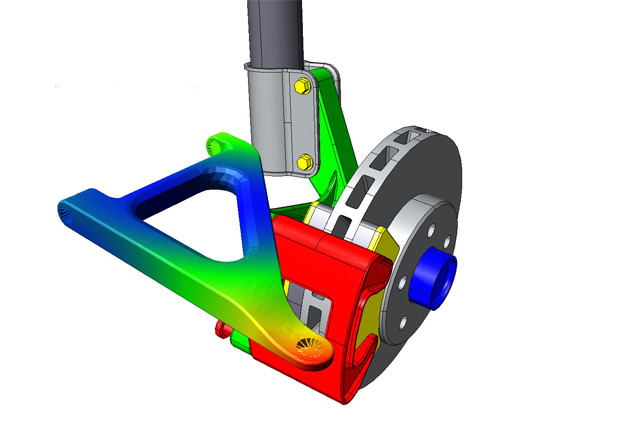

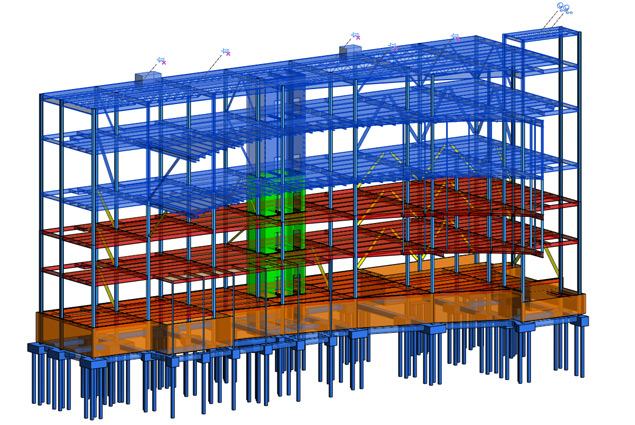

With adherence to exceptional quality standards and commitment to achieve long-¬term returns for our clients, Ideametrics offers mounded bullet FEA service as per ASME standards. Following a comprehensive understanding product specifications and code requirements, we conduct analysis for load cases including internal design pressure, the weight of empty & loaded vessels, the pressure of mound on the vessel, loads due to uneven support, and live load. Moreover, our service portfolio includes settlement of ends related to midpoints, settlement of midpoint related to endpoints, and earthquake loads. We generate reports through a thorough analysis and present solutions adhering to ASME, PD5500, and EEMAU standards.