Carbon steel and low alloy steels show a drastic change in room temperature ductility at sub-zero temperatures. This behavior is different for different types of materials. Therefore, impact testing at such service temperatures is mandatory to ensure the strength of vessel material. ASME provides some exemption for impact testing of materials in code. Unless exempted in any of the sections mentioned, impact testing is mandatory. We will discuss some exemptions given in ASME Sec. VIII Div. 1.

ASME Sec. VIII Div.1: UG-20(f)

Impact testing is not mandatory for if they satisfy all of the following,

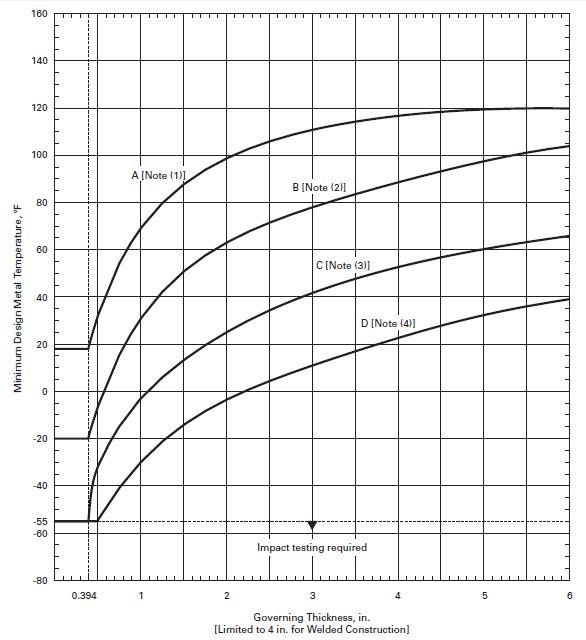

Fig. UCS-66 Impact test exemption curves [Ref: ASME Sec. VIII Div.1]

ASME Sec. VIII Div.1: UCS-66(a)

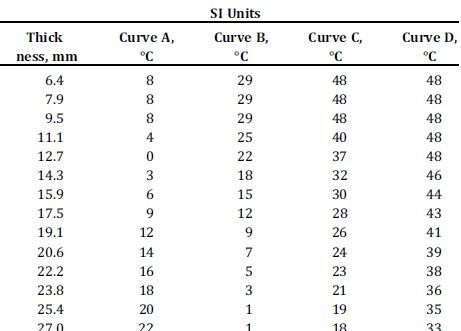

Unless exempted in UG-20(f), Fig. UCS-66 shall be used to establish impact testing exemptions for steel listed in part UCS. Impact testing is checked for the combination of minimum design metal temperature and governing thickness of the part. If the combination of MDMT and governing thickness is on or above the curve, impact testing is not required. For simplicity, the data of Fig. UCS-66 is tabulated in Table UCS-66.

Table UCS-66: Tabular values for Fig. UCS-66

Exemption for welded and non-welded parts are described in this section as follows:

ASME Sec. VIII Div.1: UCS-66(b)

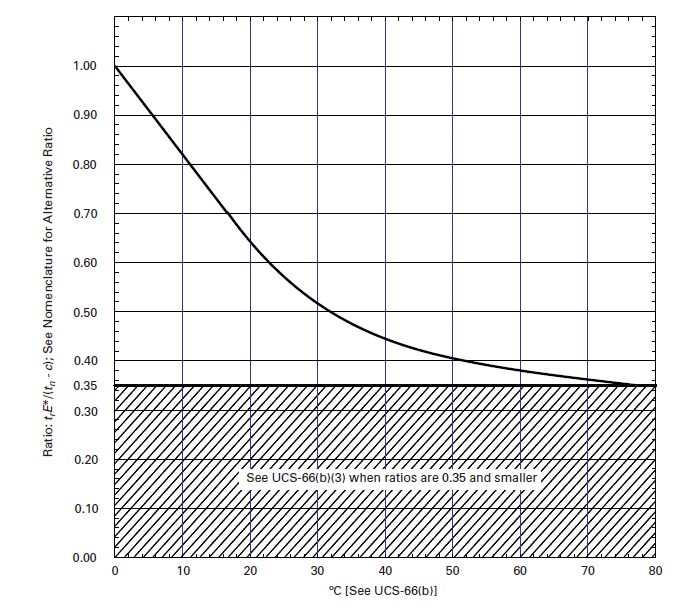

If coincident ratio is less than one, Fig. UCS-66.1 provides the basis to have colder MDMT that derived from UCS-66(a) without impact testing.

Coincident ratio = tr*E / (tn-c)

Where, tr = Design thickness

E = Joint efficiency

tn = Nominal thickness

c = Corrosion allowance

Fig. UCS-66.1 provides a reduction in MDMT without impact testing on the basis of the coincident ratio

Fig. UCS-66.1 Reduction in MDMT without impact testing

ASME Sec. VIII Div.1: UCS-66(c)

No impact testing is required for the following flanges when used at minimum design metal temperature no cooler than -29°C

ASME Sec. VIII Div.1: UCS-66(d))

No impact testing is required for UCS materials 2.5mm in thickness and thinner but such exempted materials shall not be used at design metal temperatures less than -48°C.

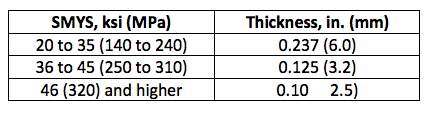

For vessels or components made from DN 100 or smaller tubes or pipe of P-No. 1 materials, the following exemptions from impact testing are also permitted as a function of the material specified minimum yield strength (SMYS) for metal temperatures of -105°C and warmer:

ASME Sec. VIII Div.1: UCS-66(c)

Unless specifically exempted in UCS-66, materials having a specified minimum yield strength greater than 450 MPa must be impact tested

ASME Sec. VIII Div.1: UCS-68(c)

If post weld heat treatment is performed when it is not otherwise a requirement of this division, a 17°C reduction in impact testing exemption temperature may be given to the minimum permissible temperature from Fig. UCS-66 for P. No. 1 materials.